Home OMiLAB Nodes OMILAB@University of Bergamo

OMILAB@University of Bergamo

The OMiLAB node at the University of Bergamo is in the field of service and manufacturing operations management, with particular reference to data-driven service operations and smart manufacturing.

About the OMILAB Node

Competences

- Process modelling and simulation

- Product-Service systems operations

- Data-drive Service engineering

- Industrial Asset Management

- Smart Manufacturing operations

About the Hosting Organisation

Results

Get an overview what this OMiLAB has accomplised! Selected results are presented below as a contribution to the global community:

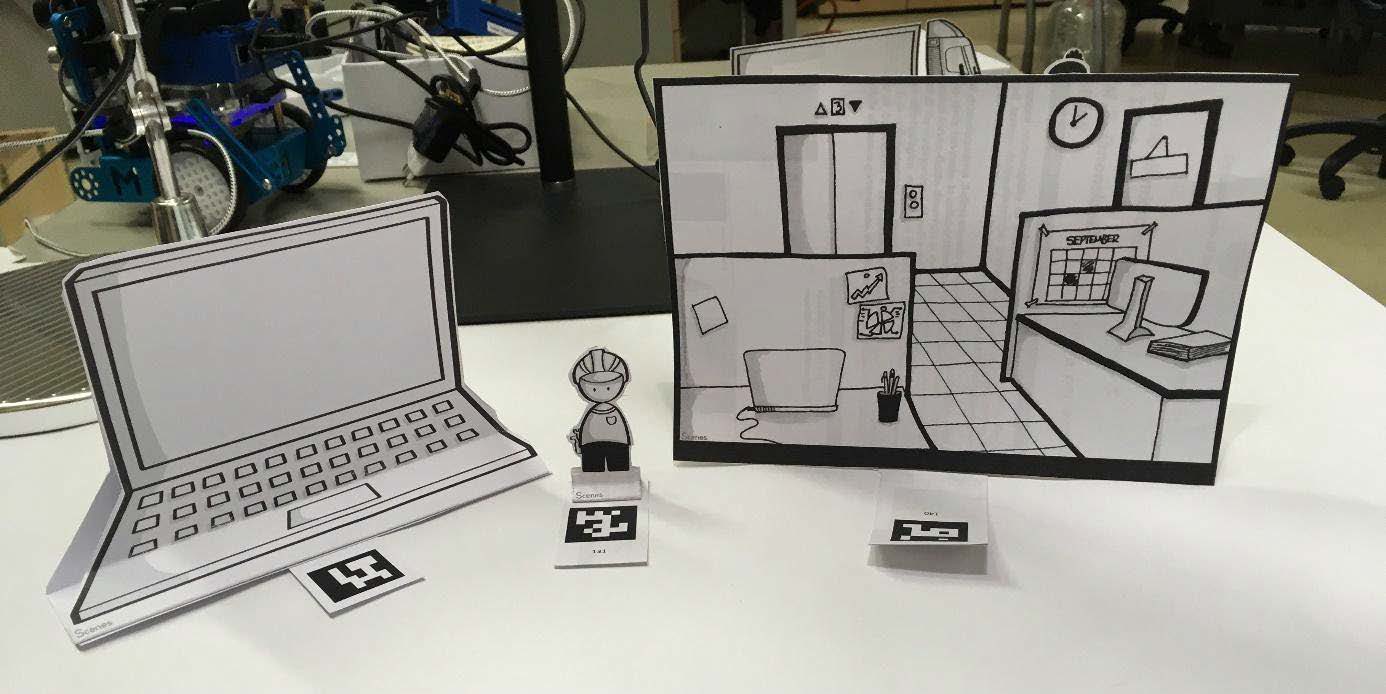

Service Engineering Methodology (SEEM) Tool

All further results of the OMiLAB Node are via the organizer.

Activities

The following, selected activities are organized by the OMiLAB.

DigiFoF Project

NEMO Summer School

Resources

The following cyber-physical resources are available at the OMILAB node:

Dobot Magician

The Dobot Magican demonstrates sorting and collaborative scenarios.

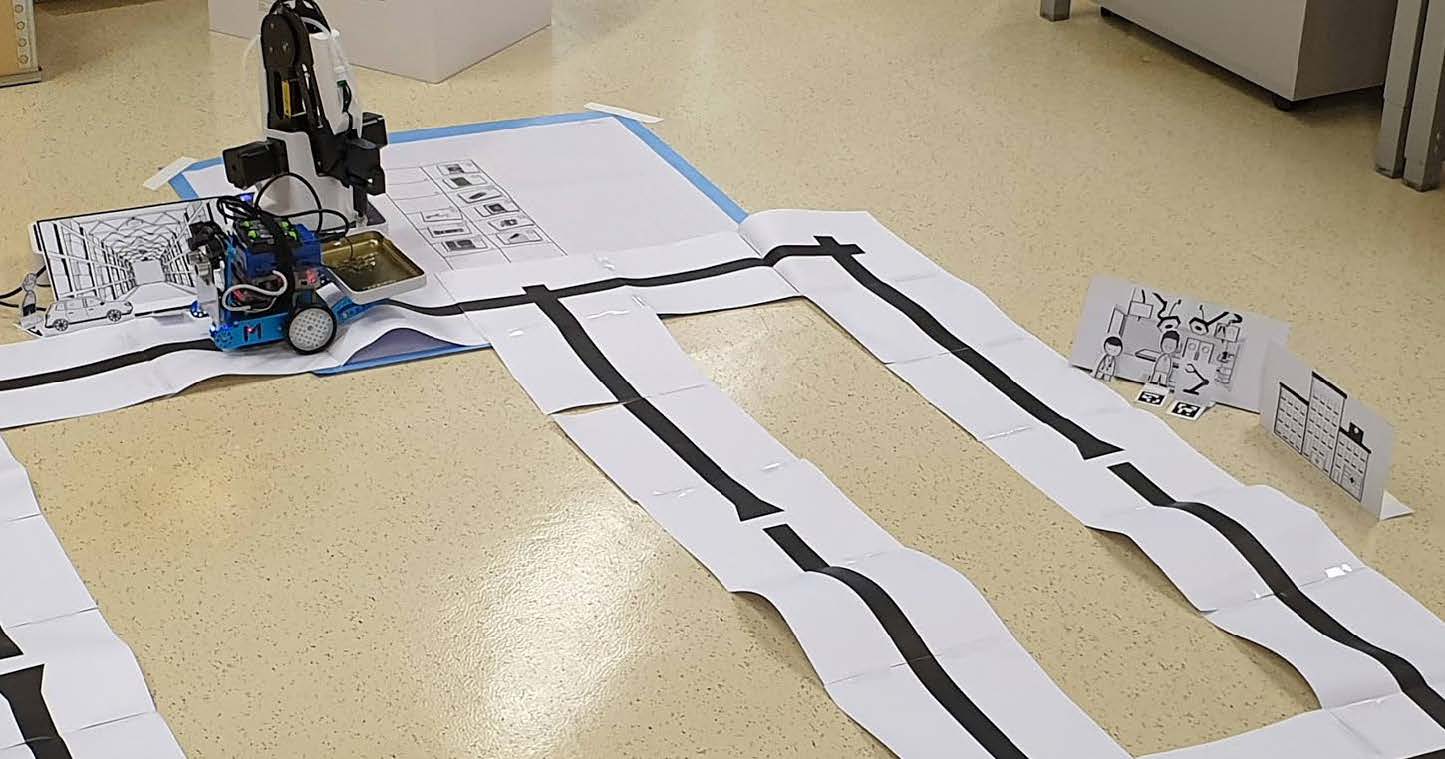

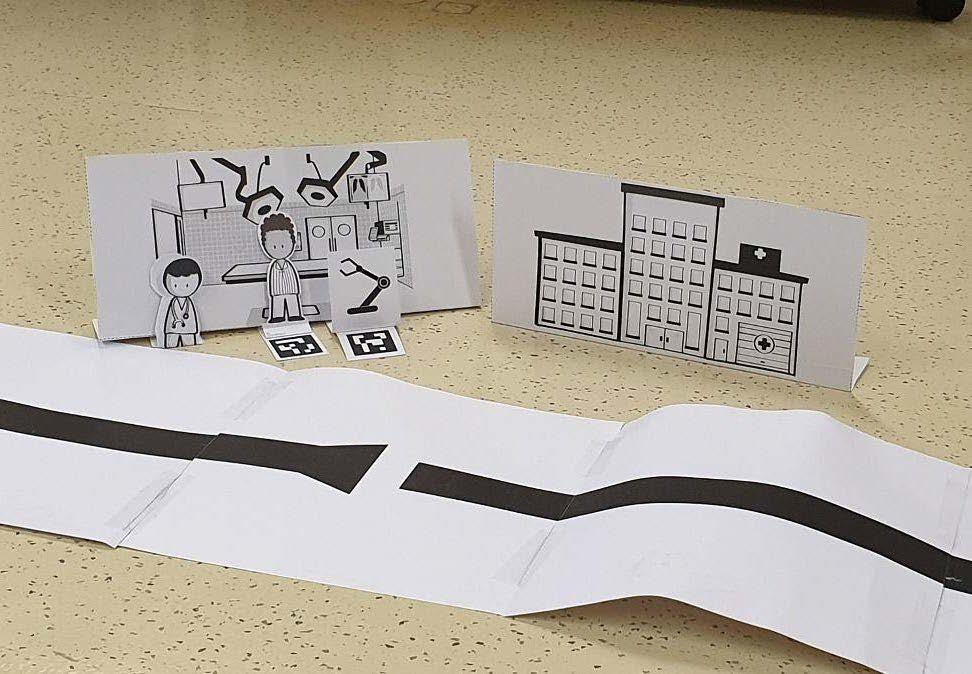

Makeblock mBot

This CPS is applied for service provision application scenarios.

Training Factory Industry 4.0

The training factory simulates a holistic production process from ordering process to production process to delivery process in digitalised and networked process steps.

Publications

Relevant publications of the OMILAB node: